How Are the wood pellets for your heating made?

Behind every wood pellet lies a carefully designed manufacturing process aimed at optimizing both energy efficiency and environmental impact. Pellets are made from recycled wood residues, mainly sawdust and wood chips from sawmills or carpentry workshops. These wastes are first dried to achieve an optimal moisture level, then ground into a very fine powder. Once reduced to powder, they are compressed at high pressure in a press, without any glue or chemical additives—the natural lignin in the wood acts as a binder. The result? Small, dense, uniform, and very dry cylinders capable of producing clean, efficient, and consistent combustion. A simple yet precise process that makes pellets a renewable and high-performance energy source.

Wood pellet manufacturing process

Wood pellets, essential for powering your heating system—whether it’s a boiler, insert, or stove—help keep your home warm during the winter. While they represent a vital source of heat, do you really know how these wood pellets are made?

Let’s explore in detail how this cost-effective fuel is created, contributing to the promotion of sustainable development. Wood pellets do not come directly from tree cutting; they are made exclusively from by-products or waste from sawmills, such as wood chips and sawdust. This is why wood pellets are a fully renewable resource, made from entirely natural raw materials managed sustainably.

One of the major advantages of choosing wood pellets as a heat source lies in their completely natural manufacturing process. To give them their characteristic small cylindrical shape, the wood residues are mechanically compressed, without the need for harmful chemicals or glue. In fact, the lignin naturally present in the wood acts as a binding agent. Some manufacturers may add starch to increase pellet efficiency while still maintaining a natural product.

After pressing, wood pellets typically measure between 15 and 25 mm in length, with a standard diameter of 8 mm. This compactness allows them to be easily stored, either in bulk or in 15 kg bags, with one ton requiring only 1.5 m³ of space. Moreover, thanks to the high-pressure compression process, their moisture content remains consistently below 10%, ensuring optimal combustion.

Once produced, wood pellets are immediately ready for use without any additional treatment, appearing clean and fully functional straight from the factory.

Discover the key steps in the wood pellet manufacturing Process

Let’s now dive into the detailed process of wood pellet production, which consists of six key steps:

Raw Material: Derived from sawmill waste and reclaimed wood, these base materials are essential for pellet production.

Transport: Quickly transporting the sawdust to the factory usually located nearby—ensures efficiency in the processing chain.

Drying: Drying the wet sawdust using either a wood-fired boiler or electricity is crucial to produce high-quality pellets.

Grinding: The sawdust and wood chips are carefully ground into a fine, homogeneous powder.

Pressing: The powder is then compressed in a cylindrical press, forming pellets under high pressure.

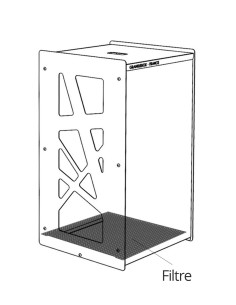

Cooling, Sieving, and Packaging: Finally, the pellets are cooled, sieved for uniform consistency, and packaged in various formats for easy use.

This rigorous and natural manufacturing process allows wood pellets to be one of the most affordable energy sources on the market while remaining environmentally friendly—an ideal solution for heating.